How Cold Plunge Chillers and Filters Work: System Design and Functionality

Understanding the Cold Plunge Chiller Definition and Functionality

Cold plunge chillers combined with filters keep water temps right where they need to be, usually somewhere between 39 and 59 degrees Fahrenheit, and they also take care of keeping things clean thanks to built in filtration systems. Traditional ice baths are a whole different story since someone has to constantly adjust the temperature manually. These newer systems work automatically because of their closed loop design, which means less hands on work for staff. Hospitals and rehab centers can actually hit those MAHC water quality guidelines from 2023 without breaking a sweat, plus they save around 30 percent on labor costs when compared to old fashioned ice based methods. Makes sense really when looking at both cleanliness standards and budget considerations.

Refrigeration Cycle in Ice Bath Chillers: How Cooling Is Achieved

The cooling process follows four stages:

- Compression: Refrigerant gas is pressurized, raising its temperature to 120–140°F

- Condensation: Hot gas releases heat through condenser coils, converting to liquid

- Expansion: Liquid refrigerant passes through an expansion valve, rapidly cooling to -20°F

- Evaporation: Cold refrigerant absorbs heat from the plunge tub water via a titanium heat exchanger

This cycle removes approximately 12,000 BTUs/hour from 100-gallon systems, based on HVAC industry benchmarks.

Water Circulation and Cooling Process in Integrated Systems

Water flows through three critical stages:

- Filtration: A 50-micron pre-filter captures skin cells and debris

- Sanitation: Ozone or UV systems neutralize pathogens before chilling

- Temperature Regulation: Chilled water returns to the tub at 6–8 GPM

The International Cold Therapy Association (2024) recommends maintaining flow rates below 8 GPM to prevent pump cavitation while achieving a cooling rate of 1°F per minute in standard 150-gallon installations.

Chiller + Filter Loop Configuration and Component Order

Optimal plumbing sequence for 95% of installations:

- Plunge tub outflow

- Sediment filter (removes large particulates)

- Circulation pump (50–100W variable-speed models)

- Refrigeration unit (preferably with copper-free heat exchangers)

- Return line with check valve

This configuration reduces pump motor failures by 42% compared to reverse-order setups and maintains temperature consistency within ±0.5°F across all components.

Core Components of a Cold Plunge Chiller and Filter System

Key components of an ice bath chiller: Pump, compressor, and heat exchanger

Most cold plunge chillers and filters work with three main parts. First up is the pump that keeps water moving back and forth between the tub and the cooling system. Without good circulation, the whole thing wouldn't function properly. Next comes the heart of the operation – usually a rotary compressor. This part pressurizes the refrigerant so it can actually transfer heat away from the water. Then there's the stainless steel heat exchanger doing the heavy lifting by swapping out thermal energy from the water into the refrigerant stream. Modern systems typically manage temperature drops somewhere around 5 to 10 degrees Fahrenheit each hour. All these pieces working together keep the water in therapeutic ranges from about 37 degrees all the way up to 55 degrees depending on what the user needs for their recovery goals.

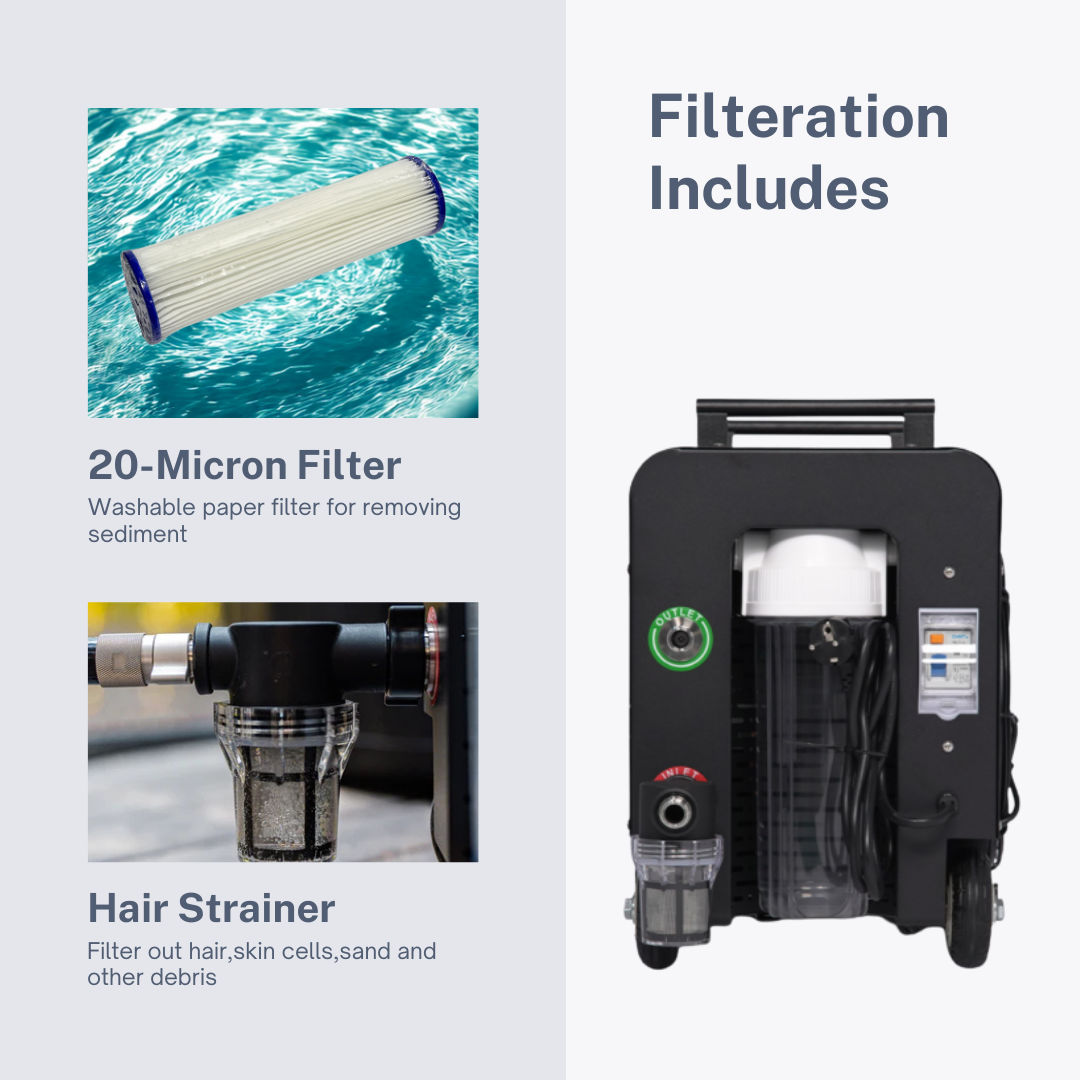

Filter systems in cold plunge chillers: Types and integration methods

Integrated filtration systems protect both equipment and users through multi-stage purification. Most systems combine:

- Mechanical filters (5–50 microns) to trap debris

- Chemical filtration (activated carbon) to remove organic contaminants

- UV-C or ozone generators for microbial control

Filters are positioned upstream of the chiller to prevent clogging in the heat exchanger. This setup complies with NSF/ANSI 50 standards for aquatic equipment, promoting hygiene and extending component life.

Ozone filtration in cold tubs: Enhancing water hygiene without chemicals

Ozone works wonders against germs, knocking them out at a rate that's roughly 3,000 times quicker than regular old chlorine, plus there's none of that lingering chemical stuff left behind after treatment. Chlorine tends to smell bad and can irritate skin, which is why many places switch to ozone when they need something they can run regularly without complaints from users. The catch? Getting ozone right takes careful control systems and special materials such as silicone tubes since other plastics just won't hold up over time. Combine ozone with good old mechanical filters though, and most labs report getting down to around 99.9% fewer microbes in their water samples. Public pools and similar facilities often go this route because it ticks all the boxes set out by those MAHC standards while still being practical enough for day-to-day operations.

Maintaining Water Quality in Cold Plunge Systems: Filtration and Sanitation

Water Hygiene, Filtration, and Disinfection Standards (MAHC, NSF/ANSI 50)

Cold plunge pools need to follow certain rules set out in the Model Aquatic Health Code or MAHC for short, along with meeting NSF/ANSI 50 standards. These regulations basically require that water gets filtered at least once every half hour and maintain specific disinfection levels for any system used commercially. The Centers for Disease Control found back in 2023 that when operators actually stick to these guidelines, they can cut down on contamination problems by around 70 something percent. The key seems to be combining good mechanical filters with enough sanitizer left in the water, typically somewhere between 1 and 3 parts per million according to most experts.

Balancing Chemical and Mechanical Filtration for Optimal Water Quality

Modern systems integrate mechanical filters (20-micron screens) with chemical sanitizers to address both particulates and microbes. High-efficiency filters capture 95% of organic impurities, reducing chlorine demand by 40% while maintaining water clarity (Water Quality Association, 2023). This dual approach minimizes skin irritation and extends water replacement intervals to 45–60 days in residential units.

Ozone vs. Chlorine in Cold Plunge Water Sanitation: Pros, Cons, and Best Practices

| Method | Effectiveness | Maintenance | User Experience |

|---|---|---|---|

| Ozone | 99.9% pathogen reduction | No daily dosing | No chemical odor |

| Chlorine | 95% pathogen reduction | Weekly testing | Potential skin dryness |

Ozone excels at preventing biofilm without altering water chemistry, making it ideal for high-traffic facilities. Chlorine remains a cost-effective option for smaller setups but requires consistent pH monitoring. Leading centers now use hybrid systems—ozone for daily sanitation and chlorine for periodic shock treatments—to optimize safety and efficiency.

System Sizing and Pump Performance for Efficient Temperature Control

Proper sizing ensures energy efficiency and reliable cooling. Oversized units waste power, while undersized systems struggle to maintain target temperatures. Key considerations include:

- Water volume (typically 150–500 gallons for commercial installations)

- Ambient temperature

- Desired chilling rate (commonly 2–4°F per hour)

Pump performance directly affects heat exchange efficiency. A flow rate of 40–60 GPM ensures optimal circulation through the evaporator coil. Variable-speed pumps adjust output based on real-time demand, reducing energy consumption by up to 30% compared to fixed-speed models.

Cooling Speed and Temperature Control: Achieving Rapid and Consistent Chilling

High-performance compressors and titanium heat exchangers enable precise temperature regulation (±0.5°F). Advanced systems reach target temperatures (50–55°F) in under two hours for a 300-gallon plunge pool. Microprocessor-controlled PID (Proportional-Integral-Derivative) algorithms continuously monitor and adjust:

- Compressor output

- Water flow velocity

- Evaporator pressure

This integration prevents disruptive temperature swings, preserving therapeutic consistency even during frequent use.

Ideal Water Turnover Rate for Hygiene and Thermal Consistency

Getting around 4 to 6 complete water turnovers each day helps keep things filtered properly and maintains even temperatures throughout the system. When dealing with a 400 gallon setup, we're talking about needing at least 26 gallons moving through every minute. Equipment certified under NSF/ANSI 50 standards cuts down on those pesky biofilms by roughly 72 percent when compared to smaller systems that don't meet these requirements. Keeping the water flowing just right stops dead spots from forming in corners where bacteria might hide, but also makes sure we aren't wasting power on overworking pumps unnecessarily.

Maintenance, Troubleshooting, and Long-Term Reliability

Routine Maintenance of Cold Plunge Chillers: Best Practices for Longevity

System lifespan depends heavily on consistent maintenance. Follow manufacturer-recommended intervals, including quarterly compressor inspections and annual refrigerant checks. Monitor performance metrics such as cooling speed and pressure levels to detect early signs of wear—systems operating below 85% efficiency often require intervention.

Adherence to maintenance schedules improves equipment longevity by 20–40% (Journal of Clinical Engineering, 2025). Combine scheduled service with real-time diagnostics:

- Thermal sensors detect refrigerant leaks or pump overloading

- Vibration analysis identifies bearing wear in circulation pumps

- Pressure logs reveal clogged filters or degraded heat exchangers

Filter Maintenance and Cleaning: Frequency and Effective Methods

Backwash filters weekly to remove biofilm and mineral buildup. In environments with ambient temperatures above 60°F, clean twice weekly. Replace components on the following schedule:

| Component | Replacement Interval | Failure Risk if Neglected |

|---|---|---|

| Sediment cartridges | 6–12 months | 47% faster compressor wear |

| Ozone diffusers | 18–24 months | 65% bacterial growth risk |

Common System Failure Modes: Diagnosing Poor Cooling and Circulation Issues

Slow cooling is often caused by fouled evaporator coils—clean quarterly with non-abrasive solutions. Circulation failures typically stem from:

- Pump cavitation (air in lines) – Bleed air valves monthly

- Clogged intake screens – Inspect during filter changes

- Voltage fluctuations – Install surge protectors, which reduce motor failure by 72%

Preventive Measures for Pump, Filter, and Refrigerant System Failures

Verify refrigerant charge annually to prevent 33% of cooling failures. For pumps:

- Lubricate bearings every 500 operating hours

- Test amp draw monthly; deviations over 10% signal potential failure

Seal all filter housing O-rings annually with food-grade silicone to prevent leaks that compromise hygiene. Systems using ozone sanitation require annual ORP sensor calibration to ensure consistent disinfection performance.

FAQ

1. What temperature should cold plunge pools be set at?

Cold plunge pools are typically set between 39°F and 59°F.

2. How often should filters in cold plunge chillers be cleaned?

Filters should be backwashed weekly or twice a week in warmer environments.

3. Can ozone be used as a standalone sanitizer in cold plunge systems?

Ozone can be used standalone for daily sanitation, but many facilities use it alongside chlorine for periodic shock treatments.

4. What are the key components of a cold plunge chiller?

The key components are the pump, compressor, and a stainless steel heat exchanger.

5. How do you maintain optimal water turnover in cold plunge systems?

Achieve 4 to 6 complete water turnovers per day to maintain hygiene and even temperatures.

Table of Contents

- How Cold Plunge Chillers and Filters Work: System Design and Functionality

- Core Components of a Cold Plunge Chiller and Filter System

- Maintaining Water Quality in Cold Plunge Systems: Filtration and Sanitation

- System Sizing and Pump Performance for Efficient Temperature Control

- Cooling Speed and Temperature Control: Achieving Rapid and Consistent Chilling

- Ideal Water Turnover Rate for Hygiene and Thermal Consistency

- Maintenance, Troubleshooting, and Long-Term Reliability

-

FAQ

- 1. What temperature should cold plunge pools be set at?

- 2. How often should filters in cold plunge chillers be cleaned?

- 3. Can ozone be used as a standalone sanitizer in cold plunge systems?

- 4. What are the key components of a cold plunge chiller?

- 5. How do you maintain optimal water turnover in cold plunge systems?