Understanding Cooling Load: How to Calculate BTU Requirements for Your Ice Bath Chiller Unit

How to choose the right size chiller for an ice bath using BTU/hr requirements

Selecting an ice bath chiller unit requires matching its cooling capacity—measured in BTU/hr—to your specific needs. The foundational formula is:

BTU/hr = Water Volume (Gallons) × 8.33 × Temperature Drop (°F)

For a 100-gallon tub needing a 30°F reduction (from 70°F to 40°F), this equals 100 × 8.33 × 30 = 24,990 BTU/hr. This calculation provides a baseline for narrowing options while allowing room for real-world variables such as user heat gain and ambient conditions.

Cooling load calculation based on water volume and desired temperature drop

Water volume directly affects energy demands. A 120-gallon system with a 25°F temperature drop requires 45% more cooling power than an 80-gallon setup under the same conditions. General guidelines by tub size include:

- Smaller tubs (≤80 gallons): 15,000—20,000 BTU/hr

- Medium tubs (80—120 gallons): 25,000—35,000 BTU/hr

- Large tubs (≥140 gallons): 35,000+ BTU/hr

These ranges reflect both volume and typical usage patterns, helping align equipment capability with practical performance expectations.

Impact of target temperature on ice bath chiller unit efficiency

When we set lower temperature targets, the system ends up working much harder and consuming more energy. For instance, bringing water down to 50 degrees Fahrenheit takes about 22 percent more BTUs per hour compared to cooling it just to 55 degrees for the exact same amount of water. Equipment running under 45 degrees typically needs bigger compressors because standard chillers tend to lose around 8 to 12% efficiency for every 10 degree drop in surrounding temperature. All these inefficiencies point to why it makes sense to invest in equipment specifically built to handle prolonged operation at colder temperatures.

Are manufacturer BTU ratings reliable? Evaluating real-world performance claims

The BTU ratings manufacturers list are just a rough guide really. Some independent tests actually found that nearly 1 out of 5 units fall short of their claimed specifications by over 15% when tested in standard ice bath conditions. What makes a bigger difference in how well these systems perform in practice? Things like the design of the heat exchanger, what kind of compressor is used, and how good the insulation is tend to matter much more than those flashy BTU numbers on paper. When dealing with important installations where performance can't be compromised, it's wise to go for chillers that come with third party certification proving they meet certain standards. This gives peace of mind knowing the equipment will deliver what it promises when it matters most.

Matching Ice Bath Chiller Unit Size to Tub Capacity (80—140 Gallons)

Chiller Sizing Guidelines for Small vs. Medium to Large Cold Plunge Tubs

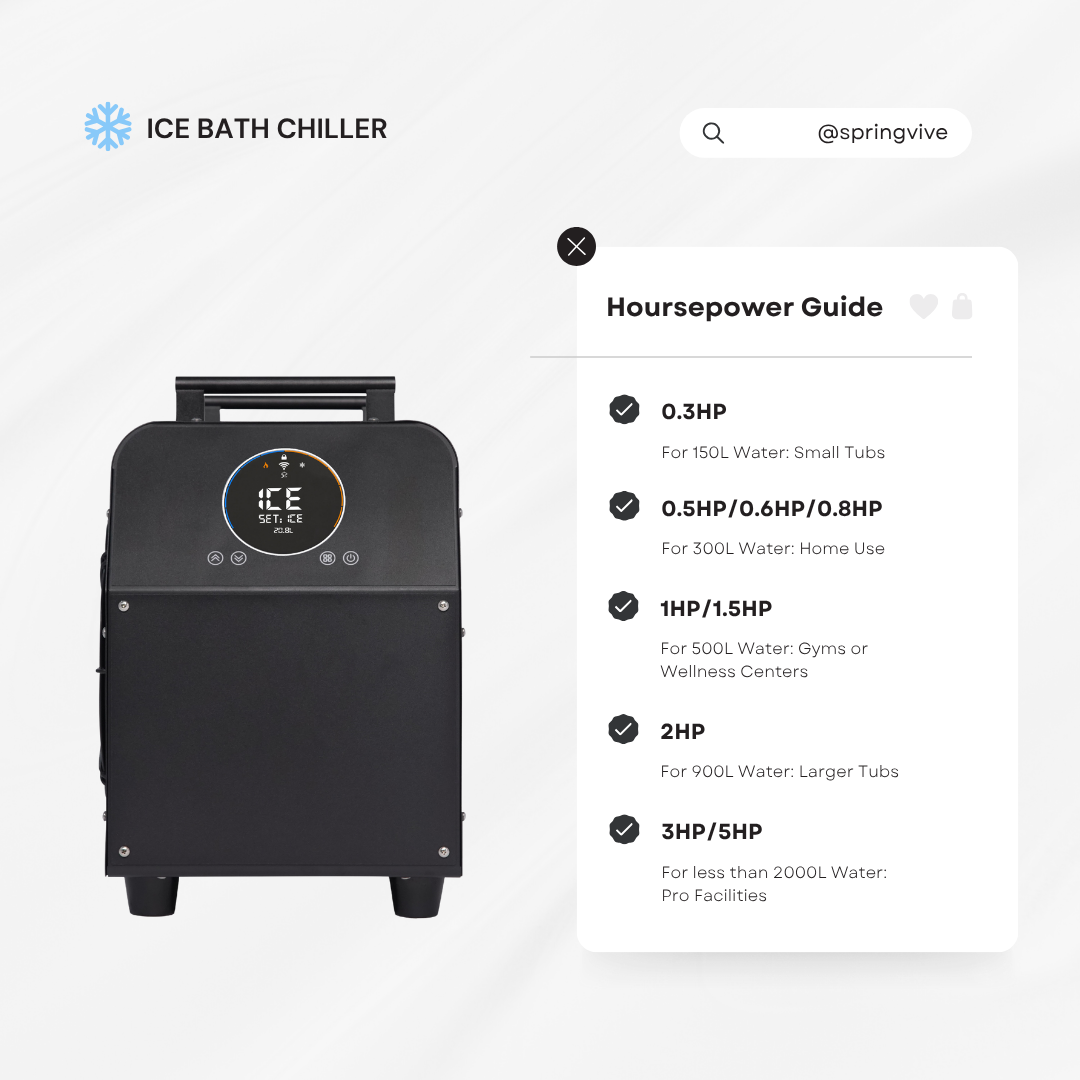

How big the hot tub is plays a huge role when picking out a chiller system. Small tubs that hold less than 80 gallons usually work fine with chillers around 0.3 to 0.5 horsepower, which translates to about 3,000 to 6,000 BTUs per hour. These smaller units are great for folks who want something simple for their backyard in places where the weather isn't too extreme. When we get to medium sized tubs holding between 80 and 140 gallons, most people find they need somewhere between half a horsepower and full horsepower chillers, roughly 6,000 to 12,000 BTUs. This keeps water temperatures steady around those comfortable 40 to 50 degree marks. The pros at major equipment companies will tell anyone serious about getting things right that if someone wants to drop the temperature another 5 degrees below standard levels, they should bump up the cooling power by about 20%. The reason? As water gets colder, it naturally resists cooling down further, so extra capacity helps combat this effect.

How Tub Volume Directly Influences Cooling Capacity Needs

Cooling 100 gallons from 70°F to 40°F requires approximately 16,000 BTUs—equivalent to 1.5 tons of refrigeration. In comparison, a 140-gallon tub needs about 30% more cooling power than an 80-gallon unit under identical conditions. The relationship between volume and required output follows a predictable pattern:

- Smaller tubs (50—80 gallons): ~75 BTU/hr per gallon

- Medium tubs (80—120 gallons): ~85 BTU/hr per gallon

- Large tubs (120—140 gallons): ~100 BTU/hr per gallon

This incremental increase reflects greater surface area and thermal mass, which elevate total heat load.

Real-World Usage Scenarios: Estimating Cooling Demands Based on Routine and Frequency

Daily use of an ice bath chiller for two 30 minute sessions when temps hit 90 degrees Fahrenheit needs about 35 percent extra capacity compared to occasional usage. The recovery period matters a lot too. Smaller chillers in those big 120 plus gallon tubs can struggle badly, sometimes needing anywhere from 2 to 3 hours just to get back down to proper temperature after several rounds of immersion. Businesses that serve five or more people each day should seriously consider doubling their initial BTU calculations. This accounts for all that constant heating and makes sure things cool down quickly enough between customers without causing delays or discomfort.

Horsepower (HP) Explained: Performance vs. Efficiency in Ice Bath Chiller Units

Comparing 0.3—0.5 HP vs. 1—1.5 HP Chillers for Home Ice Bath Setups

For most home ice bath setups, folks usually go with small 0.3 to 0.5 horsepower chillers when dealing with tanks holding between 50 and 150 gallons. The bigger 1 to 1.5 HP models come into play when someone really needs their water cooled down fast. Take a standard 0.5 HP unit for example – these things put out around 4,000 BTUs per hour. That means they can bring a 100 gallon tub down from room temperature (about 75 degrees) all the way to chilly 50 degrees in somewhere between four and six hours if everything goes smoothly. Now jump up to those larger 1.5 HP chillers and suddenly we're talking about nearly 9,300 BTUs an hour. But there's a catch. These powerhouses eat three times as much electricity and create almost half again as much noise as their smaller counterparts based on what we've seen in testing environments. Home users need to think carefully about this tradeoff between getting things cold quickly versus keeping monthly bills manageable and not driving everyone nearby crazy with the racket.

Does Higher Horsepower Mean Better Cooling? Separating Myth from Reality

Horsepower is all about how strong a motor is, not really about how much cooling it actually delivers. Take a look at chillers for instance. A 1 horsepower unit will definitely cool quicker than something with just 0.3 HP power. But here's where things get tricky. Poor design choices like weak heat exchangers or too small refrigerant lines can squander anywhere from 15 to maybe even 30 percent of what those numbers suggest on paper. Some field tests have actually found that certain half horsepower chillers beat out standard one horsepower models because they manage to extract more cooling per watt consumed. The bottom line? Sometimes better engineering beats brute force when it comes to real world performance.

Why Some Low-HP Chillers Outperform High-HP Models: Design and Engineering Factors

Four innovations allow smaller chillers to match or exceed larger units:

- Variable-Speed Compressors: Adjust cooling output based on real-time demand, reducing energy waste

- Phase-Change Materials: Store cooling potential during idle periods for rapid response

- Microchannel Condensers: Deliver 40% higher heat transfer efficiency than traditional coils

- Insulated Tubing: Minimize thermal loss during water circulation

Thanks to these advancements, high-efficiency 0.5 HP chillers now achieve outputs exceeding 6,000 BTU/hr—performance once limited to 1.5 HP units—demonstrating that smart design frequently surpasses brute horsepower.

Environmental and Operational Factors That Impact Ice Bath Chiller Unit Efficiency

Ambient Temperature and Geographic Climate Effects on Chiller Performance

Ambient temperature significantly influences chiller workload. Units maintaining 50°F water in 90°F environments require 18—22% more energy than those in 70°F settings (Journal of Thermal Efficiency, 2023). Geographic conditions further affect performance:

- Desert climates extend compressor run times by 30% during cooldown

- Coastal humidity reduces heat dissipation efficiency by up to 15%

- Elevations above 5,000 feet reduce cooling capacity by 12—18% due to lower air density

Ensuring at least 3 feet of clearance around the unit improves airflow and results in 25% faster recovery times compared to enclosed installations, emphasizing the importance of proper ventilation.

Usage Frequency, Cooldown Time, and Recovery Demands in Daily Routines

Residential chillers run for three short sessions each day actually need about 37 percent extra reserve power compared to ones only used once daily. How fast they recover temperature matters too. Chillers bringing water back to 45 degrees in half an hour eat up around twice as much energy per cycle as models taking closer to 55 minutes. And let's not forget about scale buildup. Systems in constant daily use will start losing between 8 and 12 percent efficiency every month if we don't keep them properly descaled. For chillers cooling down 100 gallons from room temperature (around 70°F) to a comfortable 50°F within 90 minutes or so, most installers recommend going with compressors rated at somewhere between 0.75 and 1.25 horsepower. Maintenance schedules vary based on usage patterns too. Machines getting used five times a week generally need filter cleanings roughly every two weeks, whereas equipment running once weekly can stretch those cleaning intervals out to about a month and a half.

FAQ

What is the basic formula to calculate BTU/hr for an ice bath chiller?

The formula is: BTU/hr = Water Volume (Gallons) × 8.33 × Temperature Drop (°F).

How does water volume affect cooling requirements?

Greater water volume increases cooling demands. For instance, a 120-gallon system with a 25°F drop needs 45% more cooling power than an 80-gallon system under the same conditions.

Are manufacturer BTU ratings always accurate?

Not always. Independent tests show some units fall short of claimed specifications by over 15%. Factors like heat exchanger design and compressor quality significantly impact performance.

How does ambient temperature affect chiller efficiency?

Higher ambient temperatures increase chiller workload and energy consumption. Units in 90°F environments need 18—22% more energy than those in 70°F settings.

Table of Contents

- Understanding Cooling Load: How to Calculate BTU Requirements for Your Ice Bath Chiller Unit

- Matching Ice Bath Chiller Unit Size to Tub Capacity (80—140 Gallons)

- Horsepower (HP) Explained: Performance vs. Efficiency in Ice Bath Chiller Units

- Environmental and Operational Factors That Impact Ice Bath Chiller Unit Efficiency

- Ambient Temperature and Geographic Climate Effects on Chiller Performance

- Usage Frequency, Cooldown Time, and Recovery Demands in Daily Routines

- FAQ