Matching Cooling Capacity to Your Ice Bath Chiller Machine Requirements

Calculating BTU/h Based on Tub Volume, Target Temperature, and Ambient Conditions

Getting the right cooling capacity sorted out stops systems from running inefficiently and wasting power. Here's how most folks calculate what they need at minimum: take the water volume in gallons, multiply that by 8.33, then multiply again by the temperature difference (ΔT) in degrees Fahrenheit, and finally divide everything by the time in hours. Need to convert liters? Just multiply by 0.264. The ΔT value comes from subtracting the desired water temp from the room temperature around it. Let's say we want to cool water down from 75°F ambient to 41°F for storage, that gives us a ΔT of 34°F. For places where things get hot quickly like gyms or old garages, many technicians recommend adding somewhere between 10% and 25% extra capacity to handle all that unwanted heat sneaking in. Don't forget about those pumps circulating water either—they generate their own heat too. And remember to check if the insulation is doing its job properly. When done, compare the calculated BTU/h number with what the actual chiller can handle on its compressor specs sheet. Nobody wants to overload equipment just because calculations looked good on paper!

Real-World Sizing Example: Chilling a 300L Tub from 75°F to 41°F in 90 Minutes

Let's start by converting those liters to gallons first. Take 300 liters times 0.264 and we get around 79.2 gallons. Now looking at our temperature difference of 34 degrees Fahrenheit over 1.5 hours, the basic math works out to about (79.2 multiplied by 8.33 then multiplied again by 34) divided by 1.5, giving us roughly 14,954 BTUs per hour. But wait, nobody wants their system underpowered, so most professionals would add a 20% buffer for things like extra heat from pumps, frequent door openings, and unpredictable insulation quality. That brings us up to approximately 17,945 BTUs. When shopping for units, round up to the next standard size available in the market, which means an 18,000 BTU unit should cover most situations adequately. However, if the facility regularly experiences quick cooldown periods after multiple people use it throughout the day, going for something closer to 20,000 BTUs might be wise to avoid those annoying thermal delays when everyone gets back.

Precision Temperature Control and Smart Interface Customization

Sub-45°F Setpoint Accuracy with Digital Thermostats and PID Algorithms

For cold therapy to work properly, the water needs to stay consistently below 45°F or around 7°C. Modern systems combine digital thermostats with something called PID control technology. These advanced controls can maintain temperature within half a degree Fahrenheit by constantly tweaking how fast the compressor runs and managing refrigerant flow. They react to changes as they happen, whether from outside temperature fluctuations or when someone interacts with the system. Basic on off systems aren't so good at this because they tend to overcool then undercool repeatedly. The PID approach keeps things much steadier throughout both quick chill cycles and longer treatment periods. This stability helps muscles recover better after workouts or injuries since consistent cold application is what actually makes the difference in reducing inflammation and promoting healing.

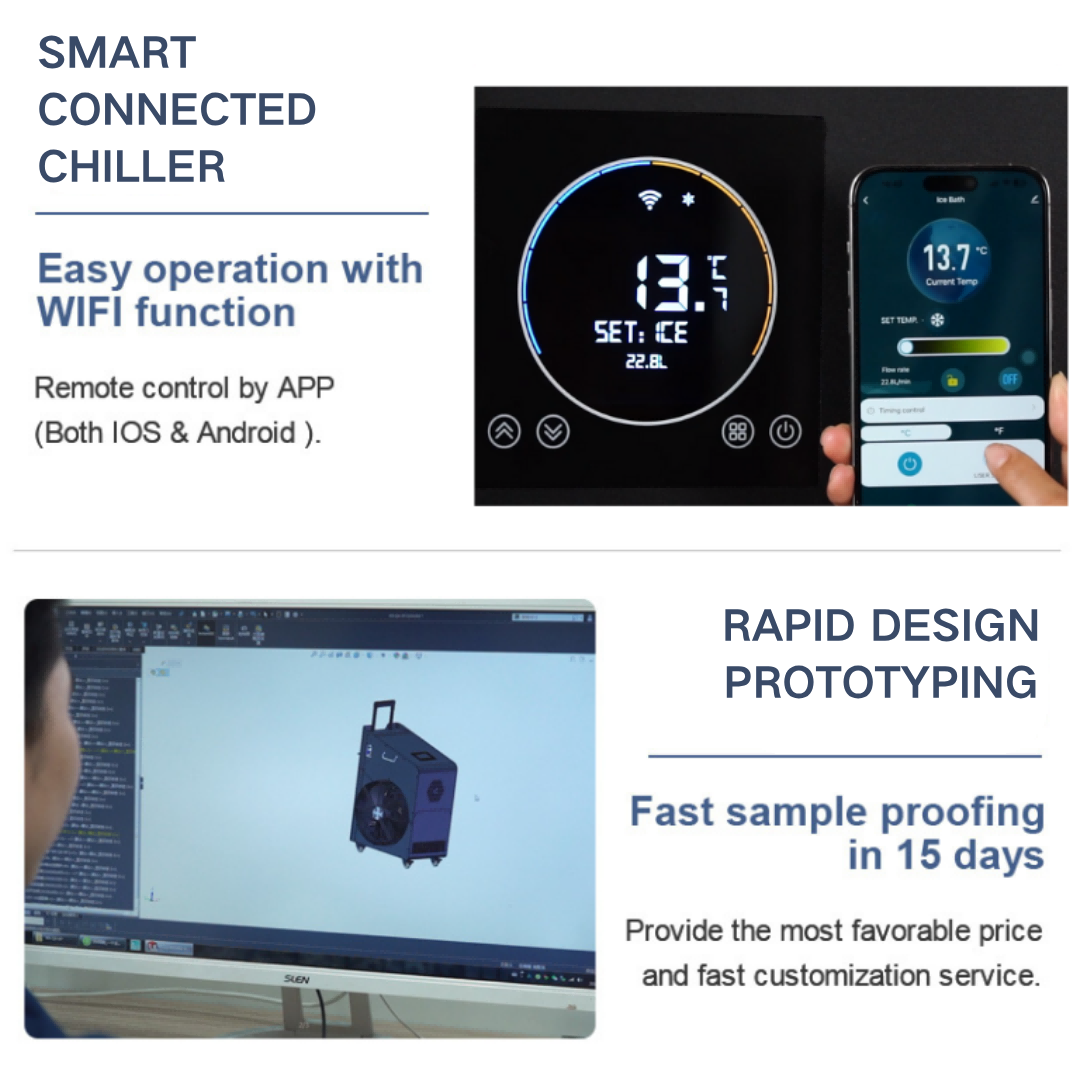

Programmable Recovery Profiles and Remote Monitoring for Commercial Use

Businesses find value in systems that offer customizable operations based on specific protocols. With programmable recovery settings, different cooling approaches can be set without needing constant adjustments. For instance, some setups might call for quick dips at 40 degrees Fahrenheit suitable for top athletes, whereas others require slower processes around 50 degrees for everyday wellness applications. Remote monitoring through smart devices gives real time temperature updates, sends warnings if temperatures drift beyond acceptable limits (usually +/- 2 degrees), and tracks how often equipment is used so maintenance can be planned ahead. Many facilities have seen their need for hands-on supervision drop by roughly 30% after implementing these technologies, all while still keeping within scientifically supported treatment parameters.

Application-Driven Design: Optimizing Your Ice Bath Chiller Machine for Use Case

Sports Recovery vs. High-Traffic Gym Deployment: Noise, Portability, and Duty Cycle Trade-offs

The setting where equipment is used really shapes what matters most in design choices. When looking at places like sports rehab centers or homes, noise level becomes super important. Units should run quietly below 50 decibels, take up minimal space, and weigh less than 30 kilograms. This makes sense when they need to be shifted around different treatment areas throughout the day. Wheels built into the base and easy access panels without tools make moving and maintaining these machines much simpler. Commercial gyms that see lots of traffic tell a different story though. They need chillers capable of running nonstop for over 16 hours each day. These require heavy duty compressors, stronger condenser coils, and better ways to get rid of heat buildup. Such systems usually make more noise, somewhere between 60 and 70 decibels, but give up being easily moved for consistent cooling power session after session. Getting the right balance between how long the system runs and how many people will use it helps avoid problems with overheating, keeps the compressor working longer, and makes sure everything stays reliable even when business is booming.

Ensuring Water Quality and Long-Term Reliability

Multi-Stage Filtration, UV Sterilization, and Easy-Maintenance Access Points

Keeping water clean isn't just about making people safe, it also helps equipment last longer. Most good systems use multiple stages of filters to catch all sorts of tiny particles and bugs. Then there's UV light treatment which kills off bacteria, viruses, and algae without needing any chemicals. This matters a lot in places where lots of different people use the same water. Equipment designs matter too. Systems that have easy access to filters from the front, UV parts that snap out quickly, and pumps that can be replaced separately save maintenance crews around 30% of their usual work time. When facilities ignore proper water care, things start breaking down faster. Corrosion sets in, heat doesn't move through pipes as well, and those slimy biofilms cause all sorts of problems. A recent study by the Ponemon Institute looked at this stuff in 2023 and found that companies losing track of their water systems end up spending over seven hundred forty thousand dollars each year on fixes they could have avoided. So investing in good filtration and easy maintenance isn't optional anymore.

FAQ

What is the importance of matching the cooling capacity to ice bath chiller machine requirements?

Matching the cooling capacity to your ice bath chiller machine requirements is important to ensure efficient operation and minimize power wastage. Proper sizing prevents system overloading and enhances overall performance.

How can I calculate the required BTU/h for my chiller?

To calculate the required BTU/h, multiply the water volume in gallons by 8.33, then by the temperature difference (ΔT) in degrees Fahrenheit, and divide by the time in hours. The ΔT is the difference between desired water temperature and ambient temperature.

What customization options are available for precision temperature control?

Precision temperature control can be achieved through digital thermostats and PID algorithms, which maintain temperatures within half a degree Fahrenheit. Programmable recovery settings and remote monitoring also provide customizable operations.