Why Regular Maintenance of an Ice Bath Chiller Unit Extends Lifespan and Ensures Performance

How consistent care prevents wear and preserves chiller unit functionality

Keeping things well maintained helps fight off the inevitable wear that comes from running machines day after day. Take those pumps and compressors for instance they get pretty beat up during every cooling cycle because of all the friction and stress involved. When we do regular lubrication checks and inspections, it takes some pressure off these components and stops them from breaking down too soon. Don't forget about cleaning those filters and coils either. Dirty ones really mess with airflow and how heat gets transferred through the system. A clean setup means everything runs smoother without making key parts work harder than necessary. All this preventive maintenance keeps systems working properly and often adds anywhere from 3 to 5 extra years onto a chillers lifespan according to industry standards.

The link between temperature regulation accuracy and routine system upkeep

Getting accurate temperature control really depends on keeping all the parts in good shape. When scale builds up on those heat exchanger surfaces, filters get blocked, or refrigerant runs low, the whole system struggles to stay at the right temperature setting. Regular maintenance keeps those sensors spotless and properly adjusted, and makes sure the heat transfer areas work as efficiently as possible. Ice bath chillers that receive proper care typically stay within half a degree Fahrenheit of their target temperature. But when maintenance gets neglected, temperatures start bouncing around quite a bit. This kind of instability doesn't just affect how effective treatments are, it actually poses risks to people using the equipment.

Common contamination sources in cold plunge water and how maintenance mitigates risk

The water in cold plunge tubs gets contaminated with all sorts of stuff from our bodies like oils, sweat, bacteria, plus whatever dirt and grime we track in from outside. All these gunk build up over time creates those slimy biofilms inside the pipes and storage tanks which makes the whole system work harder and can actually be bad for health. To keep things running smoothly, people need to change out the water regularly, swap filters when needed, and give the whole system a good cleaning now and then. Research on water quality shows that sticking to this routine maintenance cuts down bacteria levels by almost all (around 99%) so both the equipment lasts longer and everyone using it stays safer.

Industry insight: High-performance ice bath chiller units failing due to poor sanitation habits

According to industry reports, roughly 40 percent of problems with chillers happening early on aren't actually because something broke mechanically but instead come down to bad sanitation practices. When biofilms build up inside these systems, they cause all sorts of trouble including corrosion damage, blocked passages, and reduced ability to transfer heat efficiently. Even top quality chillers can struggle badly with mineral scaling if nobody bothers with proper water treatment protocols. Looking at how long equipment lasts, research suggests that chillers getting routine cleanings typically stick around for three to five extra years compared to ones left dirty. This clearly shows just how much regular maintenance affects overall system life expectancy.

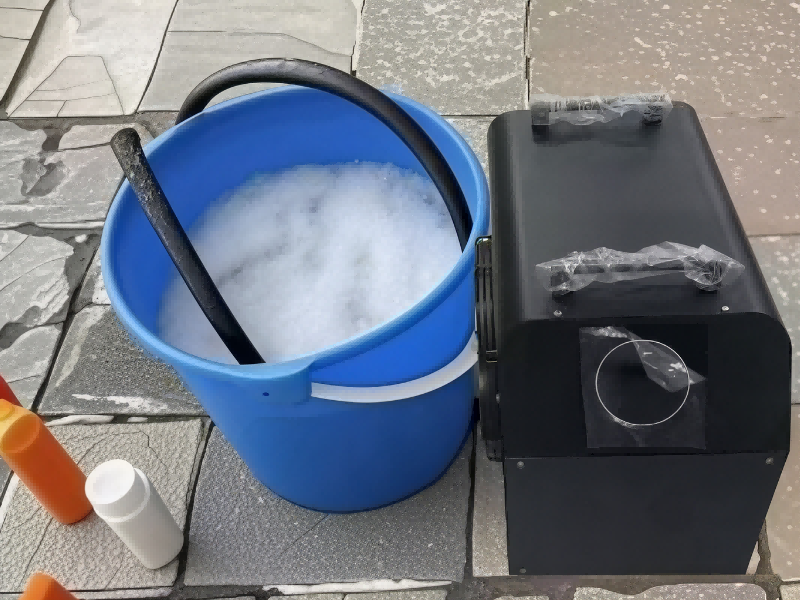

Essential Cleaning Procedures: Sanitizing Tubing, Reservoirs, and Internal Components

Step-by-step deep cleaning process for the ice bath chiller unit

First things first, turn off the system completely and let everything drain out properly. Grab a cleaner that came from the factory folks or at least one they approve of, and give those reachable spots a good going over. Don't forget the tank itself plus whatever parts inside you can actually get to without taking apart half the machine. After cleaning, flush everything well with fresh water until it runs clear. Now comes the important part - slap on some EPA registered sanitizer to kill off any bacteria hanging around. Let it work for however long the label says, which varies depending on brand. Then do another rinse cycle just to be safe, making sure no chemicals stick around. Following this whole process carefully keeps equipment running smoothly year after year instead of breaking down prematurely because someone skipped steps.

Preventing biofilm buildup through proper water quality management and cleaning cycles

Regular testing and proper filtration of water helps cut down on organic stuff that feeds biofilm growth. Set up a cleaning routine according to how much the system gets used. Places with heavy traffic might need weekly cleanups, whereas areas with lighter usage can probably get away with every other week. When possible, go for purified or filtered water sources since this cuts back on mineral buildup and those pesky microorganisms that stick around. The result? Longer time between major cleanings and better protection for the whole system. Plus, the cooling performance stays consistent over time without unexpected breakdowns.

Debunking the myth: Cold water does not self-sanitize—bacteria can thrive in chillers

Contrary to what many people think, just because something is cold doesn't mean it's clean water. Bacteria like Legionella actually stick around and sometimes multiply right in those chilly spots, especially when water sits still in pipes or storage tanks. Research from 2022 showed that nearly nine out of ten cooling systems had some kind of bacteria problem if they weren't properly maintained. Cold temps might slow down germs a bit, but they definitely don't kill them off. That's why regular cleaning and disinfecting is still so important for keeping things safe and making sure equipment works properly over time.

Filter Care and Replacement: Maintaining Optimal Flow and Water Purity

Good filtration is really important for keeping water clean and preventing dirt from getting into all those moving parts inside equipment. The majority of filtration setups rely on either PP cotton or paper cartridges to catch stuff like sediment, bits of organic matter, and tiny contaminants we can't even see. When filtration isn't working properly, all this junk builds up over time. This causes problems with water flow through the system, makes heat transfer less efficient than it should be, and eventually leads to wear and tear on pumps as well as potential issues with heat exchangers down the line.

Role of filtration in ice bath chiller units and common filter types (PP cotton, paper cartridge)

Good filtration keeps water clear and stops algae and bacteria from growing, which is important for both people using the system and the longevity of the equipment itself. Polypropylene cotton filters work by capturing small particles throughout their entire structure, so they're great at grabbing sediment and bits of organic material that would otherwise cause problems. The paper cartridge type has lots of surface area and can hold onto quite a bit of dirt before needing replacement, making them effective for filtering out larger contaminants first. When these two types work together in a system, they form a protective barrier against clogs and gradual wear on pumps, valves, and other delicate parts that might get damaged over time if left unprotected.

Recommended filter maintenance schedule based on usage and environment

Filters should be changed based on how often they're used and what kind of environment they're in. Most homes that run their systems 3 to 5 times a week will find replacing filters every 4 to 6 weeks works well enough. But businesses or places with lots of traffic might need to swap them out every other week instead. Water that's naturally hard or areas with consistently warm temperatures tend to clog filters faster, so those spots definitely need more regular attention. The best way to know when it's time for a new filter? Keep an eye on the pressure difference across the system. When this starts dropping, it means dirt and grime have built up enough to affect performance, no matter what the calendar says.

Recognizing filter failure: Odor, discoloration, and reduced flow as warning signs

When filters start failing, there are several telltale signs to watch for. The first is often a musty smell coming from the system, which usually means bacteria has started growing in the wet filter media. Water that stays cloudy no matter how long it runs through the system is another red flag. And then there's the issue of reduced flow rate. When water doesn't move through as quickly as it should, pumps have to work harder, which makes them wear out faster and reduces their ability to cool properly. If any of these things happen, it's time to check the filters right away. Most of the time, replacing them will get everything back to normal operation before bigger problems develop down the line.

Leak Prevention and Hose Integrity: Protecting Against System Damage

Inspecting and securing hoses and connections to maintain efficiency and prevent leaks

Checking hoses and fittings regularly can stop leaks before they become big problems. Most failures happen at connections that have come loose over time, gotten cross threaded during installation, or weren't properly tightened in the first place. Good quality clamps work wonders for keeping things secure, especially around joints where vibration tends to loosen everything up. Supports and those rubber protective covers really help prevent wear and tear from constant movement against metal surfaces. When running hoses through equipment areas, make sure they stay away from hot components and don't force them into tight corners since these spots tend to crack under pressure. Regular inspections catch minor issues early on, saving both time and money down the road when bigger repairs would otherwise be needed.

Effective leak detection using visual checks and pressure testing methods

Finding small leaks before they become big problems saves time and money down the road. Anyone working with fluid systems should make it a habit to walk through their facility looking for telltale signs like water pooling on floors, damp spots along pipe runs, or that distinctive rainbow sheen of oil mixed with water near connections. These simple visual checks catch issues when they're still manageable. But sometimes problems hide where the eye can't reach. That's where pressure tests come in handy. By pressurizing the system and watching for drops over time, technicians can spot leaks that would otherwise go unnoticed until they cause major damage. Most experienced maintenance teams combine these approaches as part of their regular schedule. While no one enjoys the extra work, this dual strategy pays off in longer equipment lifespan and fewer emergency repairs that disrupt operations.

Storage, Winterization, and Environmental Best Practices for Long-Term Reliability

Proper location and ventilation: How airflow and ambient temperature affect ice bath chiller unit performance

Make sure there's plenty of space around the chiller when setting it up. At minimum, leave about 12 inches clear on every side so air can circulate properly. When ambient temps climb over 90 degrees Fahrenheit (that's 32 Celsius), the cooling system starts working harder. Efficiency drops roughly 15% under these conditions, and energy bills go up as a result. On the flip side, if temperatures dip below 40 degrees Fahrenheit (around 4 Celsius), there's a real chance the internal water lines might freeze. Good airflow keeps the compressor and condenser coils from getting too hot, which helps maintain overall performance and puts less strain on all those expensive components inside the unit.

Winterization and storage protocols to prevent mold, corrosion, and internal damage

When putting something away for a long time, make sure to get rid of all water in the tank, pipes, and inside parts so it doesn't crack when cold weather hits. Run through the whole system with a special kind of antifreeze that's safe for food equipment, this helps keep those rubber seals and metal bits from rusting out. After that, give everything a good cleaning and let it dry thoroughly because damp spots can become mold problems later on. Wrap up the whole unit in a cover that lets air flow but keeps dirt and wet stuff away at the same time. Something breathable yet waterproof works best here, as it prevents buildup without trapping moisture inside.

Priming and repriming the chiller system after service or relocation to avoid dry pump operation

Before getting a pump back online after sitting idle or undergoing maintenance work, it's essential to prime it first. Get the reservoir filled up at least to its minimum required level, then go ahead and open every valve to let out any air that might have gotten stuck inside. Let the pump run for around half a minute to a full minute while keeping an eye (and ear) out for consistent water flow and strange sounds coming from the unit. If someone skips priming, they're basically asking for trouble since running a dry pump can quickly ruin seals or even fry the motor completely. Taking these few minutes to properly prepare the system actually stops one of the top reasons why pumps fail right after being stored away for extended periods.

FAQ

What is the importance of regular maintenance for ice bath chiller units?

Regular maintenance prevents wear and tear, extends the lifespan of the chiller unit, ensures accurate temperature regulation, and mitigates contamination risks.

How often should filters be replaced in ice bath chiller units?

This depends on usage and environment, but typically every 4 to 6 weeks for moderate usage, and every other week for heavy usage areas.

Do cold temperatures sanitize the water in a chiller unit?

No, cold temperatures can slow bacterial growth but do not eliminate bacteria. Regular cleaning and maintenance are necessary to ensure cleanliness.

What are the signs of filter failure in a chiller unit?

Signs include a musty odor, discoloration of water, and reduced water flow, indicating bacteria growth and clogging.

How can leaks in chiller units be detected and prevented?

Leaks can be identified through visual checks for dampness and pressure testing. Regular inspection and securing connections can prevent leaks.

Table of Contents

-

Why Regular Maintenance of an Ice Bath Chiller Unit Extends Lifespan and Ensures Performance

- How consistent care prevents wear and preserves chiller unit functionality

- The link between temperature regulation accuracy and routine system upkeep

- Common contamination sources in cold plunge water and how maintenance mitigates risk

- Industry insight: High-performance ice bath chiller units failing due to poor sanitation habits

- Essential Cleaning Procedures: Sanitizing Tubing, Reservoirs, and Internal Components

- Filter Care and Replacement: Maintaining Optimal Flow and Water Purity

- Leak Prevention and Hose Integrity: Protecting Against System Damage

- Storage, Winterization, and Environmental Best Practices for Long-Term Reliability

-

FAQ

- What is the importance of regular maintenance for ice bath chiller units?

- How often should filters be replaced in ice bath chiller units?

- Do cold temperatures sanitize the water in a chiller unit?

- What are the signs of filter failure in a chiller unit?

- How can leaks in chiller units be detected and prevented?